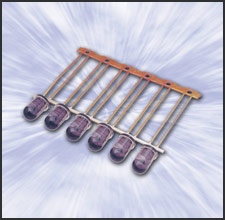

"Opto" molding compounds provide durable clarity, high product yields, superior process characteristics and high reliability for applications including image sensors, photo detectors, infrared devices, and LED displays. SolEpoxy optoelectronic encapsulants provide moisture resistance, thermal shock durability and excellent color stability even in outdoor applications and at elevated temperatures.

Strengths: Durable optical clarity, Heat stability, UV stability, & Moldability

| Unique Characteristics | Products | ||

| Typical Applications | Technical Data Sheets | ||

| Physical Properties | Material Safety Data Sheets | ||

| Color Choices |

Transmission properties can be tailored to specific wavelengths and our proprietary resin system provides outstanding resistance to yellowing even after extended exposure to UV light. We call this "Durable Clarity."

It's because, unlike other clear molding compounds the MG18 and MG97 family of products do not contain aromatic compounds. When exposed to UV light, most aromatic compounds form unstable free radicals which degrade the polymer and cause yellowing.

Color stability is crucial to devices that emit UV light such as VCSELs and white LEDs, as well as in outdoor exposure applications. Long-term thermal exposure may also cause discoloration when aromatic compounds are present. Superior color stability through UV and thermal aging is the hallmark of SolEpoxy optoelectronic encapsulants.

| Durable Clarity SolEpoxy Materials Remain Clear & Resist Yellowing Transmission at 400nm |

||

|

No aromatic compounds means:

|

|

| LED Encapsulation | Photo Detectors | |||

| 7 Segment Displays | IRDA | |||

| IR Transceivers | Image Sensors | |||

| White LED Encapsulation | Optocouplers | |||

| Photo Modules |

Transparent epoxy molding compound for light emmitting diodes, image sensors and opto sensors.

Transparent epoxy molding compound specifically designed for surface mount optoelectronic devices. Lower moisture version of MG18; great for automotive and exterior applications where temperature and humidity are widely variable.

Transparent epoxy molding compound specifically designed for surface mount optoelectronic devices, such as LEDs, image sensors and opto sensors. Lower moisture absorption and higher Tg version of MG18; great for high-intensity LEDs and sensors in hot applications.

This material is ideal for LED, opto couplers, numeric displays and IR transceivers. OP1000 provides lower moisture absorption and improved color stability over previous generation optoelectronic molding compounds.

This material is ideal for high-intensity light emitting diodes, opto couplers, numeric displays and IR transceivers. OP7000 is a pressed pellet version of MG97-8000.

| unit | MG18 | MG97-7000 | MG97-8000 | OP1000 | OP7000 | |

|---|---|---|---|---|---|---|

| Glass Transition Temp | °C | 125 | 125 | 140 | 144 | 140 |

| CTE Alpha 1, 80-100°C | ppm/°C | 70 | 72 | 72 | 74 | 72 |

| Flexural Modulus | GPa | 3.57 | 3.42 | 3.7 | 3.42 | 3.7 |

| Tensile Strength | MPa | 55.3 | 48.6 | 47.7 | 45.5 | 47.7 |

| Moisture Absorption - 24hr boil | wt% | 4.9 | 3.3 | 2.6 | 2.81 | 2.6 |

| Hardness | Shore D | 85 | 85 | 85 | 87 | 85 |

| Mold Shrinkage | % | 1.6 | 1.5 | 1.7 | 1.5 | 1.7 |

| Specific Gravity | g/cc | 1.33 | 1.30 | 1.30 | 1.29 | 1.30 |

| Dielectric Constant | 100 kHz | 3.7 | 3.4 | 3.4 | 3.43 | 3.4 |

| Dissipation Factor | 100 kHz | 0.017 | 0.016 | 0.015 | 0.016 | 0.015 |

| Dielectric Strength | kV/mm | 44.9 | 51.2 | 48.4 | 47.1 | 48.4 |

| Black | Yellow diffused | Green | |||

| Blue | Orange | Green diffused | |||

| Clear | Red | Pink | |||

| Clear diffused | Red diffused |

| Use Color-dyed Clear Epoxy to Achieve Tunable Transmittance | ||

|

|

|